What Is A Pneumatic Hydraulic Pump?

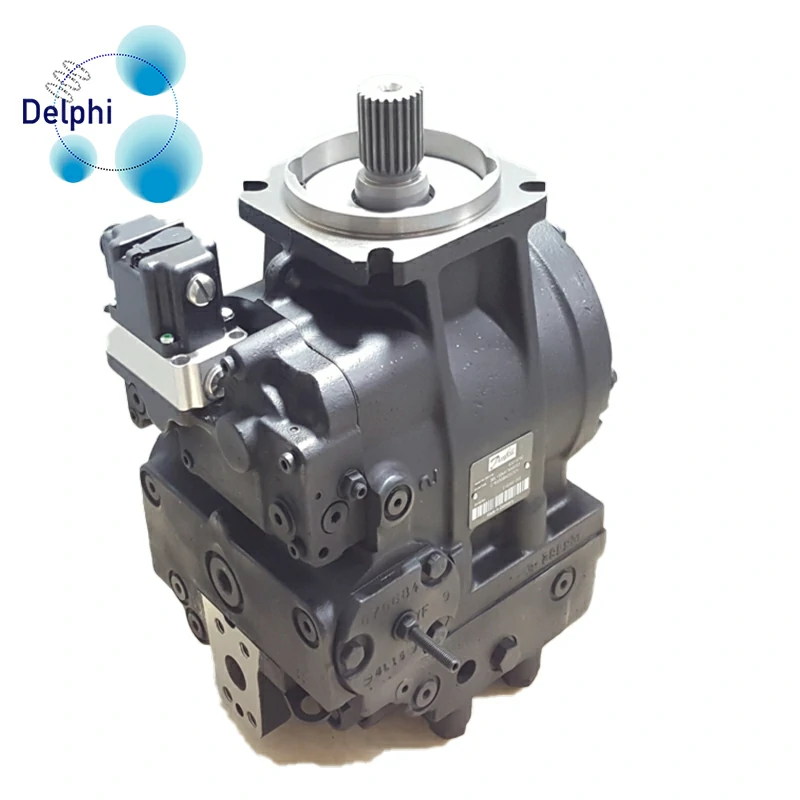

A pneumatic hydraulic pump is a type of hydraulic pump that is powered by compressed air. It works by using a piston or diaphragm to generate pressure that is then used to move hydraulic fluid through the system. Pneumatic hydraulic pumps are widely used in industries such as construction, mining, and manufacturing, where they are used to power heavy machinery and equipment.

If you need a powerful hydraulic pump that can provide 40 gallons per minute (GPM) at 3000 pounds per square inch (PSI), there are several high-quality options on the market. Here are the features to look for and some of the best 40 GPM 3000 PSI hydraulic pumps you can consider.

Why Choose A 40 gpm 3000 Psi Hydraulic Pump?

Excavators are heavy-duty machines used in construction and mining to dig, move, and transport earth and other materials. They rely on hydraulic pumps to power their hydraulic systems, which are responsible for controlling the movement of the machine. Pneumatic hydraulic pumps are a great option for excavator hydraulic pumps for the following reasons:

- High power output: A 40 gpm 3000 psi hydraulic pump delivers high power output. Then making it suitable for applications that require a lot of force to be applied to hydraulic components.

- Fast flow rate: A 40 gpm flow rate allows for a lot of fluid to be moved quickly, which is ideal for applications that require rapid movement of hydraulic components.

- Versatility: A 40 gpm 3000 psi hydraulic pump can be as used in a wide range of industrial applications. Then making it a versatile choice for many businesses.

- Durable: Hydraulic pumps are subject to a lot of wear and tear, which is why durability is an important consideration. A 40 gpm 3000 psi hydraulic pumps are as designed to withstand harsh industrial environments. And also provide reliable performance over an extended period of time.

Tips For Choosing The Right Pump

When selecting a 40 GPM 3000 PSI hydraulic pumps:

- Consider the application – What flow rate and operating pressure are actually required?

- Determine the duty cycle – How continuous versus intermittent is pump usage?

- Check environmental factors – What ambient temperatures will the pump operate in?

- Evaluate cost versus performance – Compare features, efficiency and value of different pump options.

- Consult the manufacturer – They can recommend the ideal pump model for your specific needs.