Cessna hydraulic pump parts play a vital role in the efficient functioning of hydraulic systems in aircraft, particularly in the case of Cessna aircraft models. These components are crucial for generating hydraulic power, which is essential for various aircraft systems, including landing gear, flaps, brakes, and steering. In this comprehensive blog post, we will delve into the world of Cessna hydraulic pump parts, exploring their importance, functionality, and significance in aviation. Let’s take a closer look at these essential components and their role in ensuring the safe and reliable operation of Cessna aircraft.

I. Understanding Hydraulic Systems in Cessna Aircraft

Hydraulic System Overview: Hydraulic systems in Cessna aircraft utilize fluid power to transmit force and motion, enabling the operation of critical aircraft systems. These systems rely on hydraulic pumps to generate the necessary hydraulic pressure.

Importance of Hydraulic Power: Hydraulic power is crucial for the operation of various aircraft systems, providing reliable force transmission. It enables precise control of landing gear, flaps, brakes, and other critical components, contributing to the overall safety and performance of Cessna aircraft.

II. Key Components of Cessna Hydraulic Pump

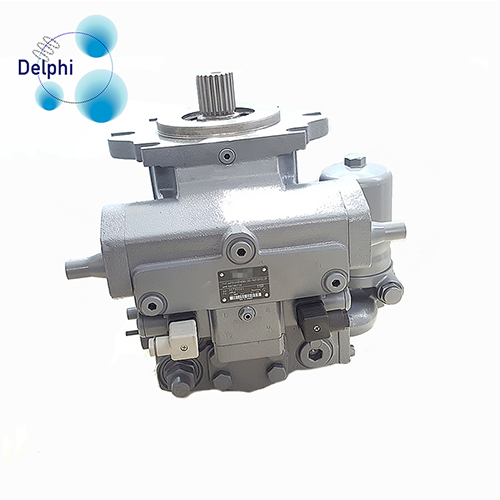

Hydraulic Pump: The hydraulic pump is the primary component responsible for generating hydraulic pressure. It converts mechanical power from the aircraft engine or electric motor into hydraulic power, supplying pressurized fluid to the hydraulic system.

Pump Drive Gear: The pump drive gear connects the hydraulic pump to the engine or electric motor, transferring the rotational motion necessary for pump operation. It ensures the synchronized functioning of the pump with the aircraft’s power source.

Pump Housing: The pump housing encloses the internal components of the hydraulic pump, providing protection and support. It contains the inlet and outlet ports for fluid flow and is designed to withstand the pressures and forces exerted during pump operation.

Vanes or Pistons: Cessna hydraulic pumps may utilize either vane or piston mechanisms to generate hydraulic pressure. Vanes or pistons, housed within the pump, create the necessary pressure by trapping and displacing fluid within the pump chambers.

III. Significance of Cessna Hydraulic Pump Parts

Reliable Performance: Cessna hydraulic pump parts are engineered to provide reliable and consistent performance, ensuring the smooth operation of hydraulic systems. These parts undergo rigorous testing and adhere to strict quality standards to meet the demanding requirements of aviation.

System Efficiency: High-quality hydraulic pump parts contribute to the efficiency of the hydraulic system in Cessna aircraft. By maintaining optimal fluid pressure, these components enable precise and responsive control of critical aircraft functions, enhancing overall operational efficiency.

Safety and Reliability: Cessna aircraft are renowned for their safety and reliability, and hydraulic pump parts play a crucial role in maintaining these characteristics. By providing consistent hydraulic power, these components ensure the reliable operation of essential flight systems, promoting safe flight conditions.

IV. Maintenance and Replacement Considerations

Regular Maintenance: Routine maintenance of Cessna hydraulic pump parts is essential to ensure their optimal performance and longevity. Regular inspections, fluid checks, and adherence to manufacturer-recommended maintenance schedules help identify potential issues early on and prevent system failures.

Genuine Replacement Parts: When replacing hydraulic pump parts in Cessna aircraft, it is crucial to use genuine parts from authorized suppliers. Genuine parts are specifically designed and tested for compatibility, ensuring proper fit, performance, and safety.

Professional Expertise: Maintenance and replacement of Cessna hydraulic pump parts should be carried out by certified aviation technicians who possess the knowledge and expertise to handle these intricate components. Professional assistance ensures proper installation and adherence to aviation regulations.